Advancements in Smart Manufacturing Innovations

- Jan 19

- 4 min read

In recent years, the manufacturing sector has witnessed a remarkable transformation driven by the integration of digital technologies. This transformation is often referred to as Industry 4.0, where traditional manufacturing processes are enhanced through automation, data exchange, and advanced analytics. As I explore these advancements, it becomes clear that the future of manufacturing lies in adopting innovative solutions that improve efficiency, quality, and flexibility. The journey toward smart manufacturing innovations is not just about technology adoption but also about strategic implementation to stay competitive in a rapidly evolving industrial landscape.

The Rise of Smart Manufacturing Innovations

Smart manufacturing innovations have revolutionized how production lines operate. These innovations leverage interconnected systems, sensors, and real-time data to optimize manufacturing processes. For example, the use of Industrial Internet of Things (IIoT) devices allows machines to communicate with each other and with central control systems. This connectivity enables predictive maintenance, reducing downtime and extending equipment life.

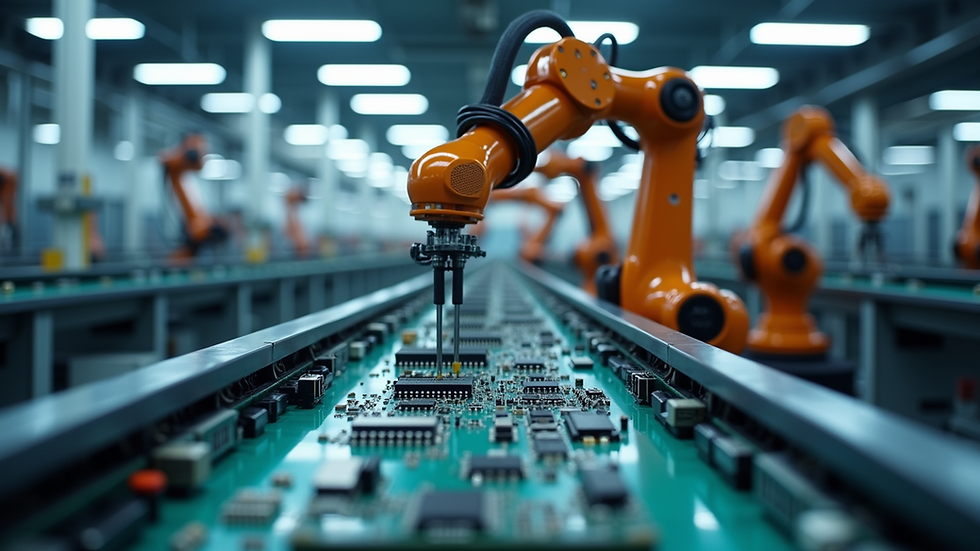

Another significant innovation is the integration of robotics and automation. Robots equipped with advanced sensors and artificial intelligence (AI) can perform complex tasks with high precision and speed. This reduces human error and increases production throughput. Additionally, automation allows for flexible manufacturing systems that can quickly adapt to changes in product design or demand.

The implementation of digital twins is also gaining traction. A digital twin is a virtual replica of a physical asset or process that can be used to simulate, analyze, and optimize performance. By using digital twins, manufacturers can test changes in a virtual environment before applying them on the shop floor, minimizing risks and costs.

Key Technologies Driving Smart Manufacturing Innovations

Several core technologies underpin the advancements in smart manufacturing innovations. Understanding these technologies is essential for companies aiming to modernize their operations.

Artificial Intelligence and Machine Learning

AI and machine learning algorithms analyze vast amounts of data generated by manufacturing equipment. These insights help in quality control, demand forecasting, and process optimization. For instance, AI can detect anomalies in production data that indicate potential defects, allowing for immediate corrective actions.

Additive Manufacturing (3D Printing)

Additive manufacturing enables the creation of complex parts with reduced material waste. It supports rapid prototyping and small-batch production, which is particularly valuable for customized products or components with intricate designs.

Advanced Sensors and IoT

Sensors collect real-time data on temperature, pressure, vibration, and other critical parameters. When connected through IoT networks, this data provides a comprehensive view of the manufacturing environment, facilitating better decision-making.

Cloud Computing and Edge Computing

Cloud platforms offer scalable storage and computing power for processing manufacturing data. Edge computing complements this by processing data locally at the source, reducing latency and enabling faster responses to operational changes.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies assist in training, maintenance, and design visualization. For example, AR can overlay instructions on machinery during maintenance, improving accuracy and reducing downtime.

These technologies collectively contribute to creating a more agile, efficient, and resilient manufacturing ecosystem.

Implementing Smart Manufacturing Innovations Successfully

Adopting smart manufacturing innovations requires a well-planned strategy. It is not enough to simply invest in new technologies; companies must also focus on integration, workforce readiness, and continuous improvement.

Assessment and Planning

Begin by assessing current manufacturing capabilities and identifying areas where smart technologies can add the most value. Develop a roadmap that aligns technology adoption with business goals.

Pilot Projects

Implement pilot projects to test new technologies on a smaller scale. This approach helps in understanding potential challenges and benefits before full-scale deployment.

Workforce Training

Equip employees with the necessary skills to operate and maintain new systems. Training programs should focus on both technical skills and change management.

Data Management and Security

Establish robust data governance policies to ensure data quality, privacy, and security. Protecting sensitive manufacturing data is critical in a connected environment.

Continuous Monitoring and Optimization

Use analytics tools to monitor performance and identify opportunities for further improvement. Smart manufacturing is an ongoing journey that requires regular updates and refinements.

By following these steps, companies can maximize the return on investment in smart manufacturing innovations and maintain a competitive edge.

The Role of Data Analytics in Enhancing Manufacturing Efficiency

Data analytics plays a pivotal role in unlocking the full potential of smart manufacturing innovations. The vast amount of data generated by connected devices can be overwhelming without proper analysis. Advanced analytics tools transform raw data into actionable insights that drive better decision-making.

For example, predictive analytics can forecast equipment failures before they occur, allowing for proactive maintenance scheduling. This reduces unplanned downtime and lowers maintenance costs. Similarly, quality analytics can identify patterns that lead to defects, enabling process adjustments to improve product quality.

Moreover, analytics supports supply chain optimization by providing visibility into inventory levels, supplier performance, and demand trends. This visibility helps in reducing lead times and minimizing stockouts or overstock situations.

To leverage data analytics effectively, companies should invest in:

Data Integration Platforms that consolidate data from various sources.

Visualization Tools that present data in an understandable format.

Advanced Algorithms tailored to specific manufacturing challenges.

The integration of data analytics into manufacturing processes ensures that decisions are data-driven, timely, and aligned with operational goals.

Preparing for the Future of Manufacturing

Looking ahead, the evolution of smart manufacturing innovations will continue to accelerate. Emerging technologies such as 5G connectivity, quantum computing, and advanced AI models will further enhance manufacturing capabilities.

To prepare for this future, companies should:

Stay Informed about technological trends and industry best practices.

Invest in Scalable Infrastructure that can accommodate new technologies.

Foster a Culture of Innovation that encourages experimentation and learning.

Collaborate with Trusted Partners who can provide expertise and support during digital transformation.

By embracing these principles, manufacturing companies can navigate the complexities of Industry 4.0 and position themselves for long-term success.

In conclusion, the integration of smart manufacturing technologies is reshaping the industrial landscape. The advancements discussed here offer practical pathways to enhance productivity, quality, and flexibility. As you consider your own manufacturing operations, remember that the journey toward smart manufacturing innovations is continuous and requires commitment, strategic planning, and collaboration.

The future of manufacturing is smart, connected, and data-driven. It is a future that you can confidently embrace with the right approach and trusted guidance.

Comments