Smart Manufacturing Advancements Transforming the Electronics Industry

- Jan 26

- 3 min read

The electronics industry is undergoing a profound transformation driven by smart manufacturing advancements. These changes are reshaping how products are designed, produced, and delivered. As manufacturing processes become more intelligent and interconnected, companies are positioned to achieve higher efficiency, better quality, and greater flexibility. This blog post explores the key aspects of this transformation, providing insights and practical guidance for those navigating this evolving landscape.

The Impact of Smart Manufacturing Advancements on Electronics Production

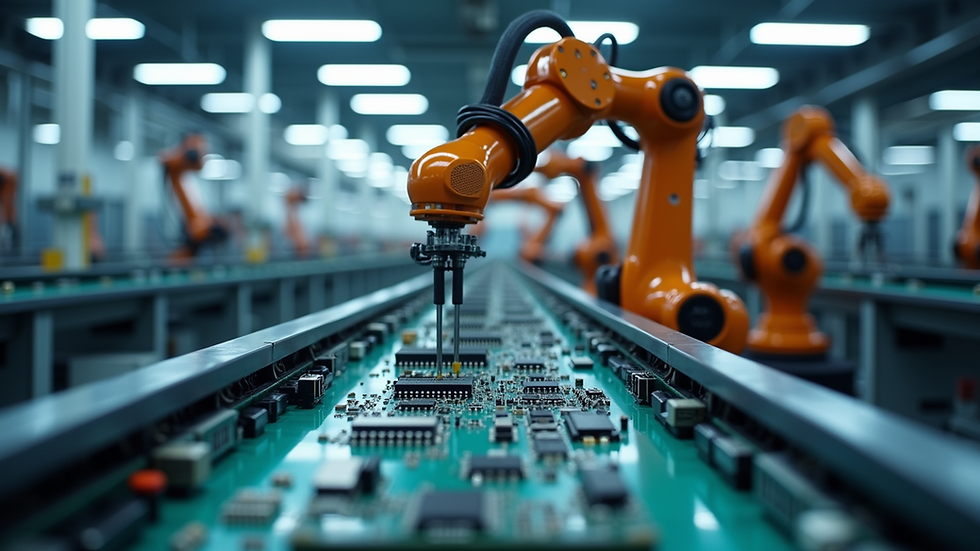

Smart manufacturing advancements have introduced a new era of automation, data exchange, and real-time decision-making in electronics production. These technologies enable factories to operate with increased precision and reduced waste. For example, the integration of sensors and IoT devices allows continuous monitoring of equipment health, preventing unexpected downtime. Additionally, advanced robotics and AI-driven systems optimize assembly lines, ensuring consistent product quality.

One significant benefit is the ability to customize products rapidly without sacrificing efficiency. Electronics manufacturers can now respond to market demands with agility, producing smaller batches tailored to specific customer needs. This flexibility is essential in an industry characterized by rapid innovation cycles and diverse product portfolios.

To leverage these advancements effectively, companies should invest in scalable digital infrastructure and workforce training. Emphasizing data analytics capabilities will also empower decision-makers to identify bottlenecks and optimize operations continuously.

Key Smart Manufacturing Advancements Driving Change

Several technologies underpin the smart manufacturing revolution in the electronics sector. Understanding these advancements is crucial for companies aiming to stay competitive.

Industrial Internet of Things (IIoT): IIoT connects machines, sensors, and systems, enabling seamless data flow and real-time monitoring. This connectivity supports predictive maintenance and quality control.

Artificial Intelligence and Machine Learning: AI algorithms analyze vast amounts of production data to optimize processes, detect defects early, and forecast demand trends.

Additive Manufacturing: Also known as 3D printing, this technology allows rapid prototyping and production of complex components, reducing lead times and material waste.

Digital Twins: Virtual replicas of physical assets enable simulation and testing of manufacturing scenarios, improving design and operational efficiency.

Advanced Robotics: Collaborative robots (cobots) work alongside human operators, enhancing precision and safety in assembly tasks.

Cloud Computing: Cloud platforms facilitate data storage, processing, and sharing across multiple locations, supporting global manufacturing networks.

By integrating these technologies, electronics manufacturers can achieve higher throughput, lower costs, and improved product reliability.

What are the six pillars of smart manufacturing?

Smart manufacturing is built upon six foundational pillars that collectively enable the transformation of traditional production systems into intelligent, adaptive environments.

Connectivity: Establishing robust communication networks among machines, devices, and systems to ensure seamless data exchange.

Visibility: Gaining real-time insights into production processes through sensors and monitoring tools.

Transparency: Sharing accurate and timely information across departments and supply chains to enhance collaboration.

Predictive Analytics: Utilizing data-driven models to anticipate equipment failures, quality issues, and demand fluctuations.

Adaptability: Designing flexible manufacturing systems capable of adjusting to changing requirements and conditions.

Agility: Responding quickly to market changes and customer needs by streamlining workflows and decision-making.

Each pillar supports the others, creating a comprehensive framework that drives continuous improvement and innovation in electronics manufacturing.

Practical Steps to Implement Smart Manufacturing in Electronics

Implementing smart manufacturing requires a strategic approach that balances technology adoption with organizational readiness. Here are actionable recommendations to guide this process:

Assess Current Capabilities: Conduct a thorough evaluation of existing equipment, IT infrastructure, and workforce skills to identify gaps.

Define Clear Objectives: Establish measurable goals such as reducing downtime, improving yield, or accelerating product development.

Prioritize Technology Investments: Focus on solutions that offer the highest return on investment and align with business objectives.

Develop Data Management Strategies: Ensure data quality, security, and accessibility to support analytics and decision-making.

Train and Engage Employees: Provide ongoing education and involve staff in change initiatives to foster acceptance and innovation.

Collaborate with Trusted Partners: Work with experienced consultants and technology providers to navigate complex digital transformation challenges.

By following these steps, companies can build a resilient foundation for smart manufacturing that drives sustainable growth.

The Future Outlook for Electronics Manufacturing

The trajectory of smart manufacturing advancements suggests a future where electronics production is increasingly autonomous, efficient, and customer-centric. Emerging technologies such as edge computing, augmented reality, and blockchain are expected to further enhance transparency and control.

Moreover, sustainability will become a central focus, with smart manufacturing enabling reduced energy consumption, minimized waste, and circular economy practices. Companies that embrace these trends will not only improve their operational performance but also meet growing regulatory and consumer demands for responsible manufacturing.

In this evolving environment, partnering with experts who understand the complexities of digital transformation is essential. Such collaboration ensures that investments in smart manufacturing technologies translate into tangible business benefits.

Smart manufacturing is no longer a distant vision but a present reality reshaping the electronics industry. By adopting these advancements thoughtfully, you can position your operations for long-term success and resilience.

For more detailed insights on how to integrate these technologies, consider exploring resources on smart manufacturing for electronics.

header.all-comments